BOOK AND PAINTINGS: EXPERIENCING OXFORD

Categories Book: Experiencing Oxford Printing Process

Printing Process

Printing Experiencing Oxford in Malta on February 5th 2010

The Guttenberg Press, who are printing the book, generously invited Conor Gallagher (book designer) and Ian Davis (author) to come to Malta in February 2020 to check the final proofs and watch the book being printed.

There was also time to have a brief look round at the rich landscape and the fine stone architecture of Malta and its magical twin island, Gozo, in bright winter sunshine. The buildings are a similar honey colour to Oxford’s limestone.

Valetta Harbour

Looking towards the harbour in Valetta

Bay windows, Valetta

Mgarr Harbour, Gozo

Restored windmill in Xaghra, Gozo

Cathedral in the Citadel, Victoria, Gozo (1716)

Dwejra, Gozo

The Printing Process

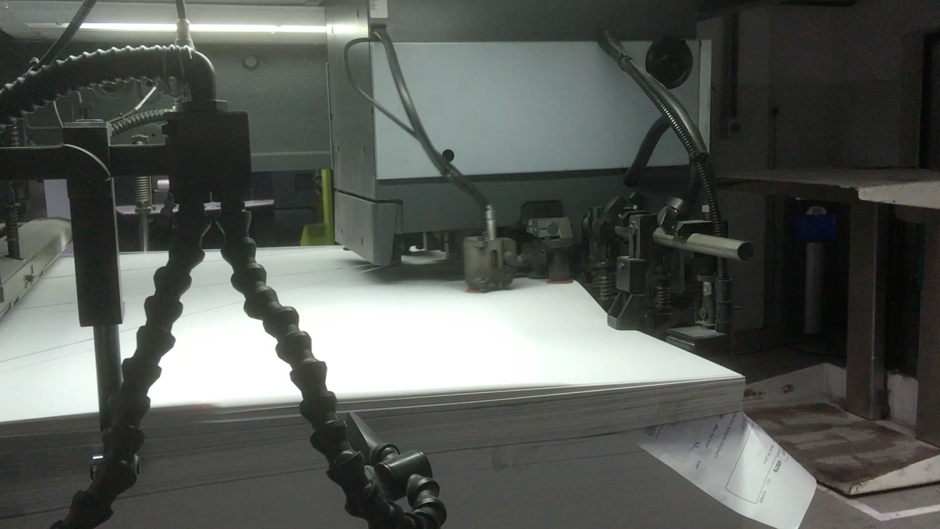

Gutenberg Press

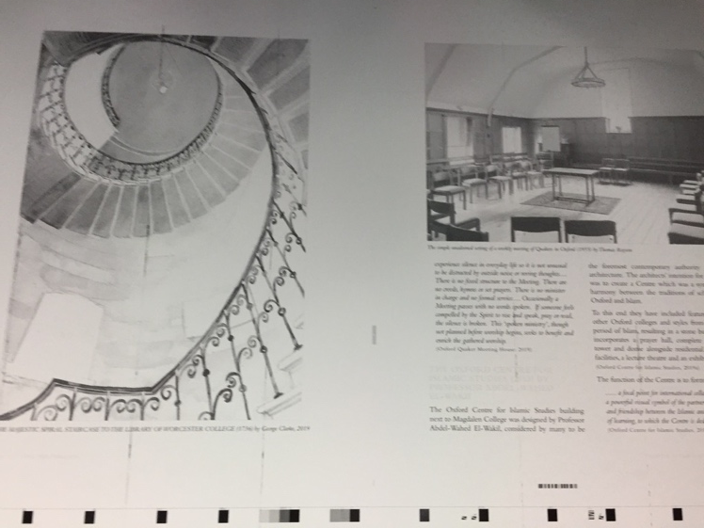

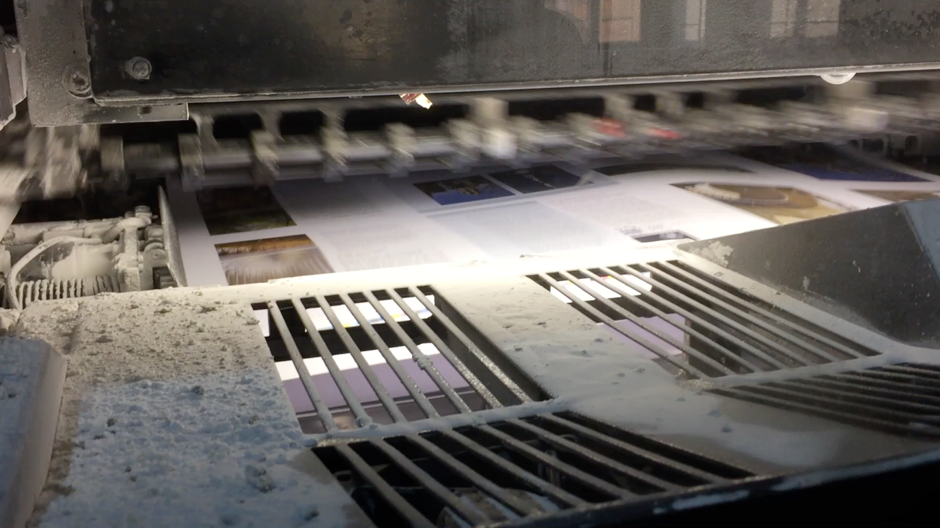

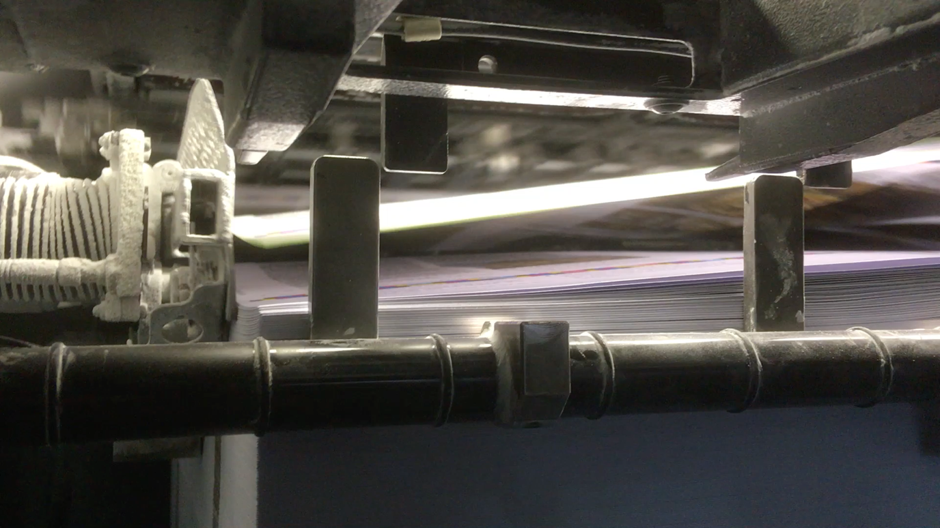

Bank of printers to simultaneously print both sides of sheets in four colours: black, cyan, yellow and blue. Powder is inserted between each sheet to help in the ink drying process. The print machine takes about 15 minutes to print 1000 copies of each of the twenty sections of the book

Conor discussing a background colour with the printing team

Ian Davis inspecting the cover to see if it accurately represents his cover painting

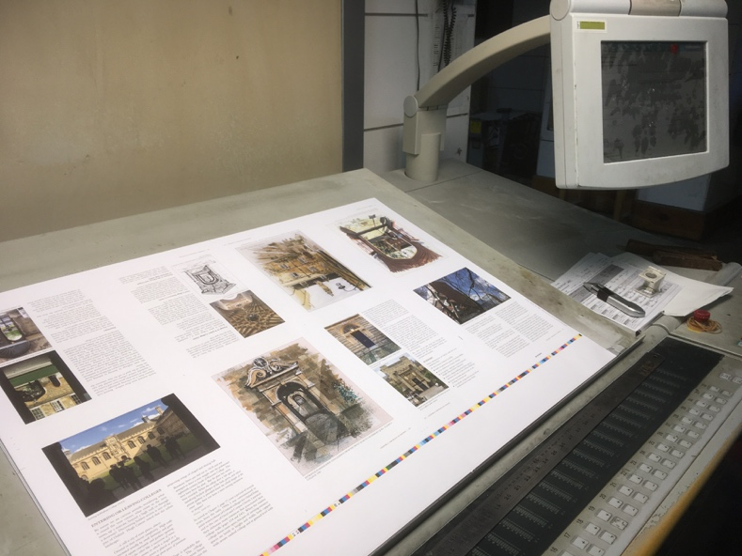

Before each print run, a skilled technician inspects the proof visually and a computer scan identifies any faults in the settings to be adjusted prior to the run

Aluminium sheets are used for each of the four colours in Chapter 10. They are only used once, after the printing they are recycled:

Black sheet

Yellow sheet

Cyan sheet

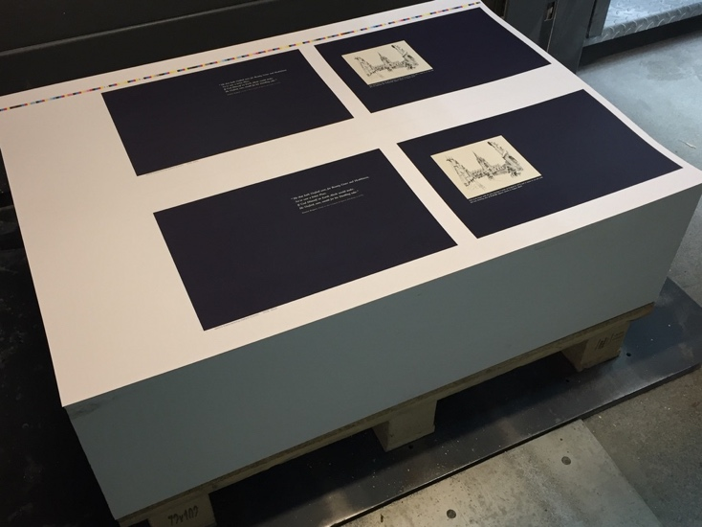

Completed piles of printed sheets waiting for the next stage, stitching the twenty sections together, pressing and trimming the pages then applying the cover with glue

Some lessons from the day watching the printing process:

- It is a rapid process, virtually the entire book of 320 pages was printed in a single day

- The book is printed on 20 sheets then chopped up. Each of the twenty sheets contains 16 pages of the book, 8 pages on each side of the sheet

- All the colour reproduction is achieved from just four colours, in a similar manner to a typical home printer

- The inspection and adjustment of final proofs is a combination of a scrutiny by the skilled eyes of the printing technicians as well as the use of a computer scan to reveal any errors to be corrected

- The aluminium sheets for each of the four colours for each sheet are only used one, if a reprint is needed the entire process is repeated

Conor and Ian wish to thank the staff of Gutenberg for enabling them to watch the printing taking place.